147° - Housse de Couette Today - 220 x 240cm, 100% Coton, Dune

13€ - Amazon

Taille 220X240 cm

Couleur Dune

Type de tissu 100% Coton

Marque TODAY

Taille 220X240 cm

Couleur Dune

Type de tissu 100% Coton

Marque TODAY

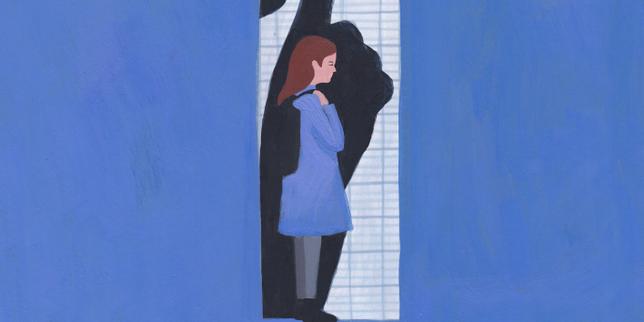

© RAFAEL YAGHOBZADEH POUR « LE MONDE »

© « LE MONDE »

© Sylvie Serprix

© REUTERS

© Dave Winter / Icon Sport

© Sarah Meyssonnier / REUTERS

© ALAIN JOCARD / AFP